CAPABILITIES

Although we feel Nine-W has the people and tools to cope with almost anything thrown at us, we can roughly break ourselves down to 3 major categories

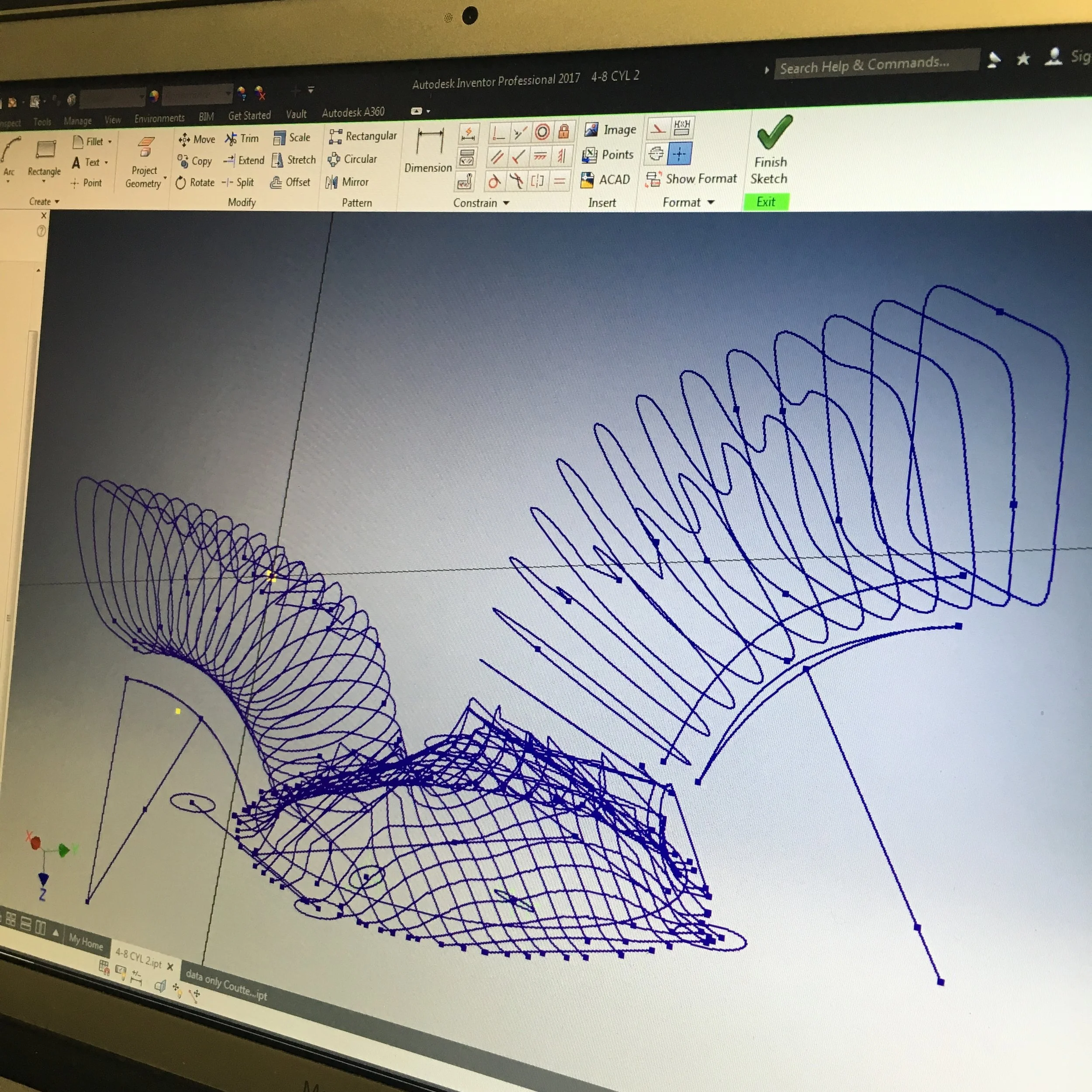

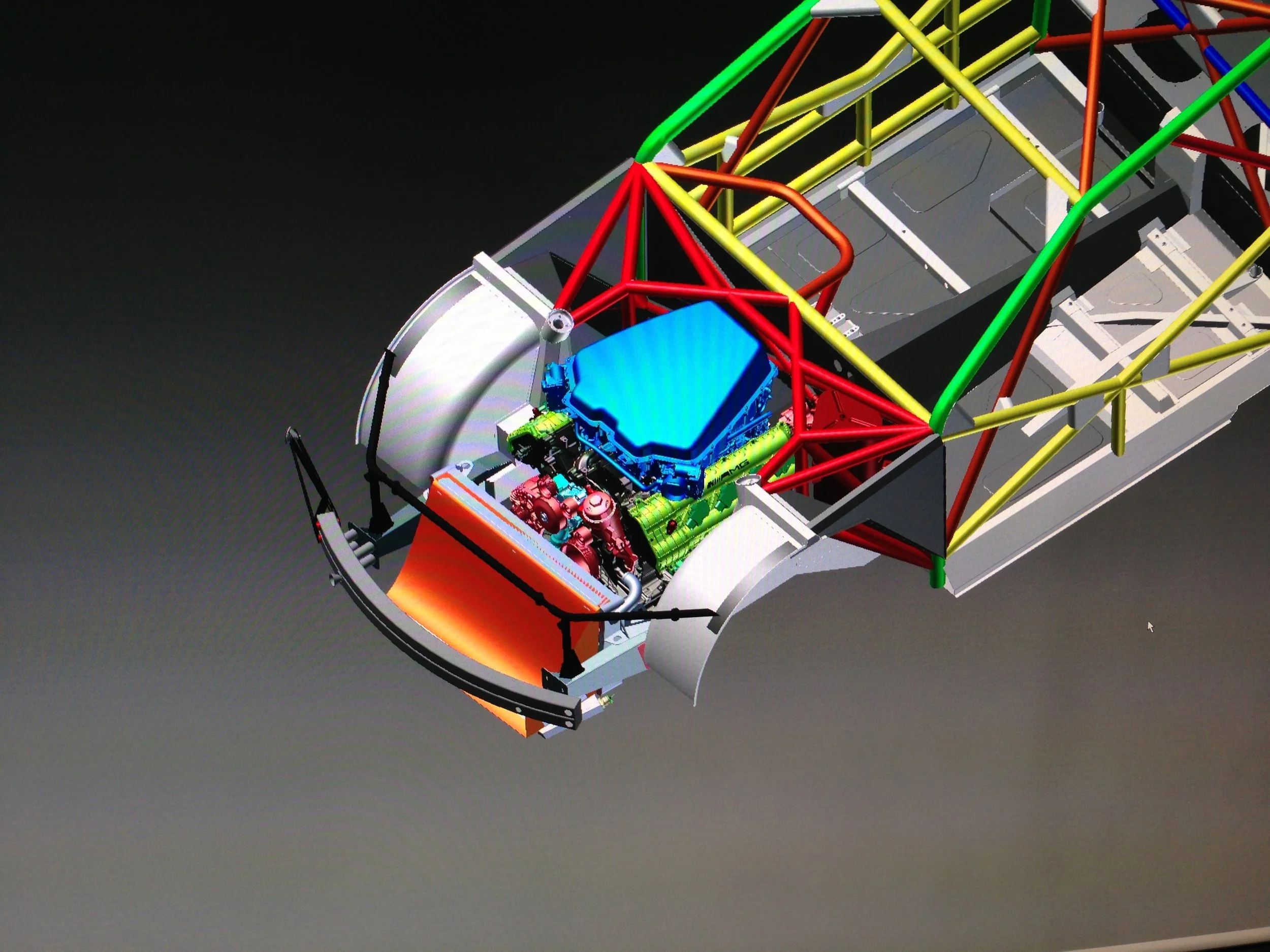

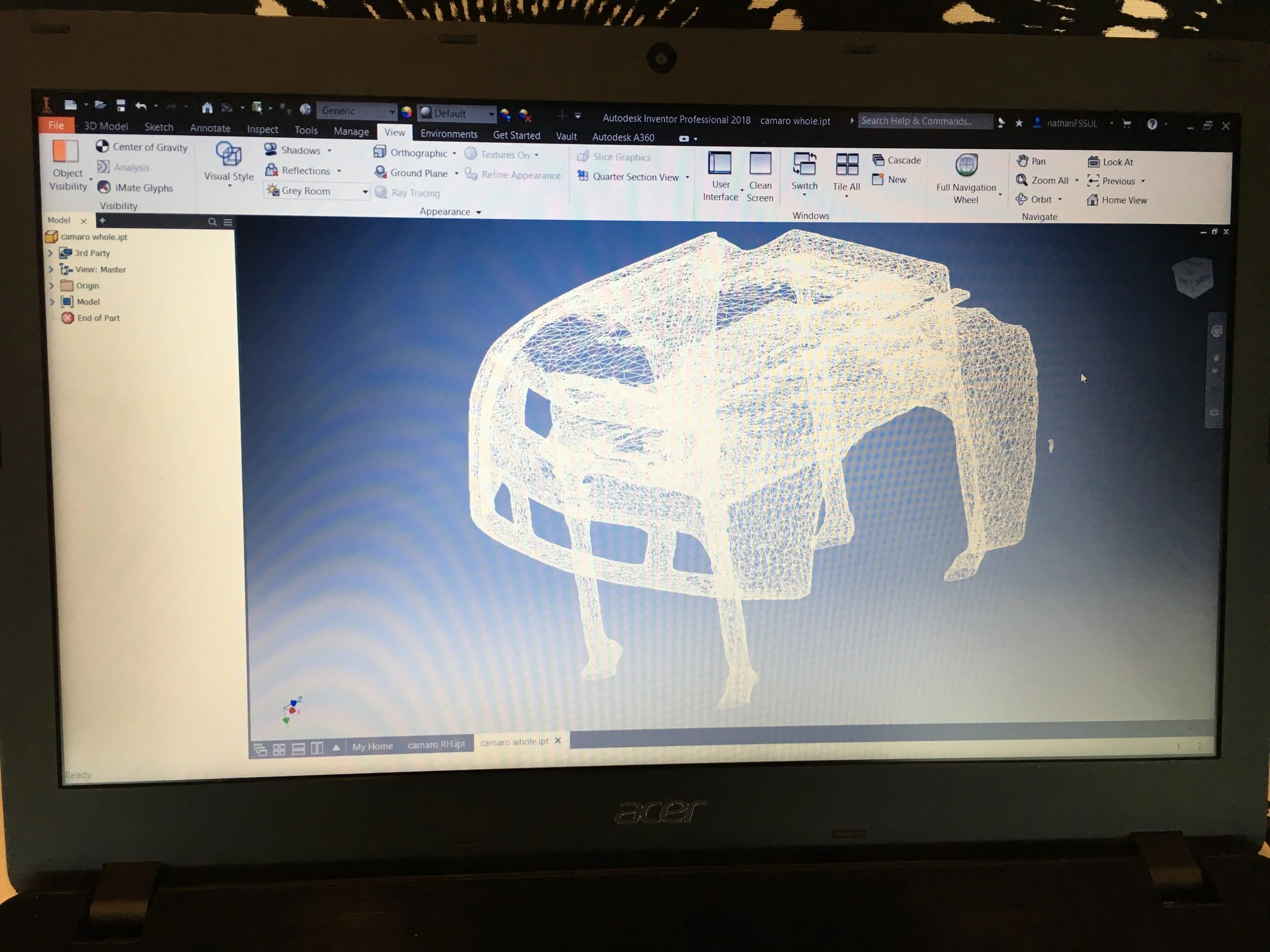

CAD

Nine-W uses the latest suite of Autodesk Inventor products to virtually prototype, mathematically test and create production drawings. We are proficient and heavily experienced in modelling to suit all variety of manufacturing techniques including CNC machining, fabricated parts, carbon molding and additive manufacture.

In addition to 3D modelling and simulation software, Nine-W has hardware and software for completing reverse engineering and prototype designs. Our inhouse laser scanning and photogrammetry capabilities suit archive based CAD, retrofitting of parts and reproduction. We have several plastic printers to suit a variety of materials and tasks for prototyping and production.

What makes the design and prototype experience unique and ultimately successful at Nine-W is our years of practical experience and myriad of projects completed. With our background in motorsport, we can adapt to all means of manufacturing techniques, timelines and budget variations to suit all clients.

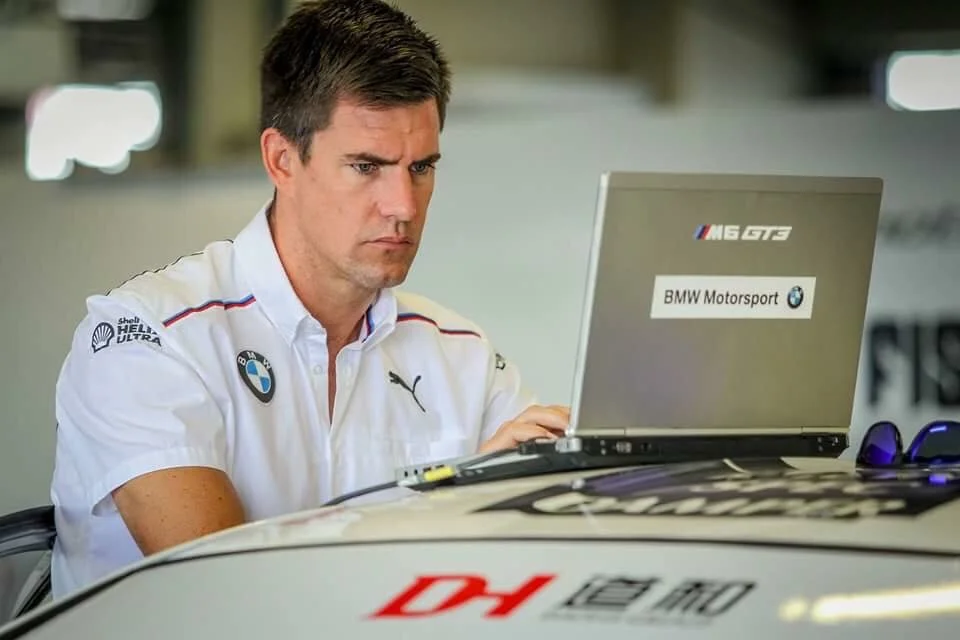

Track Support .

Nine-W engineers have spent time at race track all over the world. From championship winning V8 Supercar, factory backed GT3 supported efforts, right down to local

Manufacture

From more than a decade in the design and manufacture space, Nine-W has built a vast network of likeminded suppliers to complement our list of in house capabilities. We take advantage of both local and international manufacturers to fulfil our clients’ needs. Mitigate your risk by letting Nine-W do the dirty work and supply end products to your every requirement.

Our inhouse capability at Nine-W HQ include a full chassis jig for build, repair and audit. Using a modular, beam style jig allows us to quickly form adaptions to any conditions or projects. Our designers and fabricators have superior experience in exotic materials often seen in high end welded assemblies. We have undertaken all manner of project including repair of modern FIA-GT3 cars, thin wall chromoly spaceframes to complete carbon bodywork fitment for legality and aerodynamics.

Nine-W digital fabrication tools include both additive and subtractive machines. We have in-house plastic printing including the Mark 2 by MarkForged. This printer is a world first in its ability to print continuous weave carbon fibre. We also use Creality CR-10 large format FDM machine for multiple materials for prototyping and end product uses.